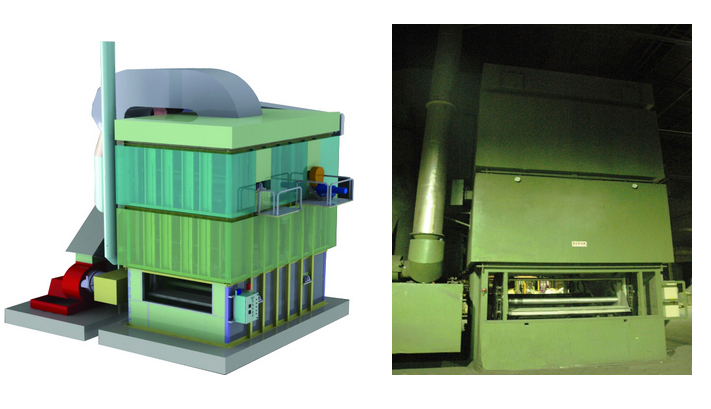

VERTICAL TYPE- CHAINED CONVEYORED CORE DRYING SYSTEM

Air circulation is realized by pressing the drying air drawn in the cell from the discharge vents and shaping the air by absorbing it from the collection vents after the water vapor is loaded. To revise economically, 20% of the recycling air that is converted into cells is sent off in the channel that passes through the grown.

| USEFUL DIMENSIONS | : 3000 X 2700 X 8200 mm |

| ENERGY TYPE | : Doğal Gaz |

| MAX. TEMPERATURE | : 200 °C |

| CONTROL | : Automatic. Big Flame - Small Flame - Off |

| CAPACITY | : 20 moving shelves wıth a loading capacity of 750 kg |

| AUTOMATION |

: Temperature is monitored from 4 differents spots on the furnace

Conveyor speed can be adjusted from the control panel Burner switches in and off automatically. Loading and unloading of the heavy parts will be done with a forklift. During loading and unloading forklift operator will be able to stop and start the system with a remote controller. When one shelf reaches the loading point, warning will be given via siren and light. |